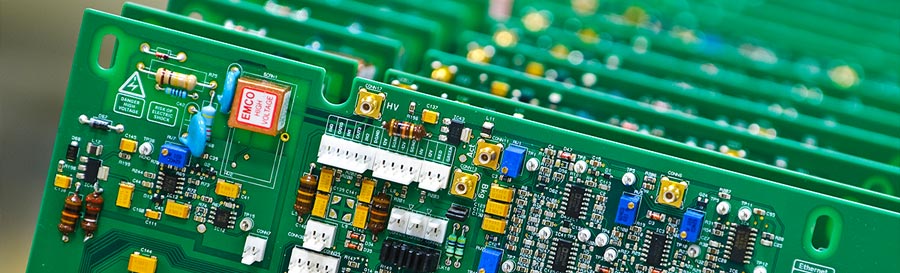

Providing Turn-key PCB Assembly Solution

Aicom Electronics is capable of providing full turn-key and partial turnkey PCB assembly services. For full turn-key, we take care of the entire process, including preparation of Printed Circuit Boards, procurement of electronic components, online order tracking, continuous monitoring of quality and final assembly. Whereas for partial turn-key, the customer can provide the PCBs and certain components, and the remaining parts will be handled by us.

With Aicom Electronics PCB’s Full Turnkey whatever Prototype or Low Volume PCB Assembly , PCB, & PCB Assembly capability, you can go from concept to product to market in just a few easy steps. Upload your BOM file and get a Full Turnkey, PCB, or PCB Assembly price for components, labor and bare boards; it’s that simple. Our team of procurement specialists scours their sources to locate the exact parts you’re looking for, at the best price available on any given day.

With Aicom Electronics PCB’s Full Turnkey, PCB, & prototype PCB Assembly capabilities, we can take your most complex project and turn it around for you within a single day. We offer full turnkey PCB, PCB Assembly quotes online or over the phone. Aicom Electronics PCB’s Full Turnkey ‘Solution’ includes PCB design, PCB, PCB Assembly and DFM engineering assistance. Aicom Electronics PCB PCB also provides inspection, test, and beyond, including box build and final pcb assembly if desired.

How to obtain a quote for one-stop PCB assembly services?

PCB Online Quote: An Instant PCB price can be quoted base on Board information .

PCB Assembly Quote: This is an additional instant quote for the cost of labor for PCB assembly.

BOM Pricing: To get a BOM price within 24 hours, email the BOM to sale@aicom-electronics.hk and include all details such as quantities, reference designators, and manufacturer name and part number.

Most entrepreneurs and manufacturers find the old ways of manufacturing electronics and to printed circuit board assembly very intimidating because it is slow, prone to errors, and expensive. It wasn’t designed for small batch runs and prototypes, but to support enormous orders with a long lead time. Luckily, the services of Turnkey Printed Circuit Board (PCB) assembly are coming in today to meet the needs of hardware designers.

What is Turnkey Printed Circuit Board Assembly?

It is a new method to an electronic assembly that influences onshore PCB manufacturing and cloud-based software to generate emerging printed circuit boards stress-free and fast for entrepreneurs, manufacturers, engineers, and small enterprises. With this, you need just to upload the design of your files and receive a quote instantly and the rest will be under the care of the manufacturer.

Turnkey PCB assembly is taken beyond just the boards by some services and offer the service essential to come out with your completed products. Your product will be assembled as needed and the record of your part will be kept.

An Example of a company that offers Turnkey PCB assembly is Aicom Electronics PCB which equally assembles SMT designs.

Benefits of Turnkey PCB Assembly

Hardware designers are happy because of the new opportunities offered by Turnkey PCB assembly. Some of these outstanding opportunities include:

1. Instant Quotes

Speed in mind wasn’t added to the design of traditional methods of PCB manufacturing. Usually, just to know how much their order would cost, designers had to wait for a long time. But with the new Turnkey PCB assembly, this is not the case. Here, you can find out the cost of your order as soon as the file of the design is uploaded into the online portal belonging to the seller.

2. Prototyping

The production of your first prototype is usually a very slow and expensive process. With this, chores such as out-of-stock electronic components, slow lead-times, and keeping up with many sellers all around the world become tedious. With Trunkey PCB assembly, you can now prototype more efficiently and effectively. It has never been easy to iterate your product and to get to the market affordably and quickly.

3. Online Ordering, Tracking, and Reporting

An online portal which streamlines documents management, ordering, and tracking, facilitates an instant PCB assembly. You are able to sign in and view the real-time status of your work, and as the work reaches key milestones, you’ll receive email notifications and alerts.

4. One seller to Manage

The Turnkey method to printed circuit board construction implies that you’ll need not to worry about managing many sellers. This is particularly a benefit if the seller will have to assemble your final product. Miscommunication, delay, frustration, and disappointments are issues of the past.

5. Order 1 or 10,000 PCS

Also called Kickstarter manufacturers or cloud manufacturers, Turnkey PCB assembly manufacturers possess systems that can bring small orders together and combine them into a big run. Your partner in Turnkey PCB assembly will be excited to manufacture your design in the desired amount once the design is perfect. As your business grows, you can keep the same partner.

6. Shipping Services, Inventory, and Assembly of Products

Also, the final shipping services, inventory, and assembly, and of products are offered by top-tier rapid PCB manufacturers. Without counting a reel or touching a box, you are able to ship in materials and components, make complicated products, and review your inventory. An API is offered by some vendors so as to integrate with your e-commerce or ERP solutions. Without any stress or delay on your part, the customer’s order is shipped directly from the manufacturer.

People who can use Turnkey PCB Assembly

Anybody with a design can quickly and affordably bring out their new ideas because this new method to printed circuit board manufacturing eliminates the limitations of quantity and cost inherent in the legacy system. For startups and small enterprises that want to bring their products to market without risk and cost of big inventories, Turnkey PCB assembly is just the idle approach to use.

Also, it is good for Kickstarter manufacturers who might not know whether they’ll require just hundreds or few boards. The flexibility and speed of instant PCB construction are also enjoyed by producers and hobbyists. Engineers in large enterprises also see it to be faster, easier and, fascinating than traditional approaches.

From concept to Delivery

The producers control the whole process with turnkey PCB assembly. This process includes component procurement, PCB fabrication, packaging, Prototype PCB assembly, fulfillment, and testing. When you have the right partner, you can remove the hassle of storing, purchasing and tracking your inventory along with the complications and delays built-in with the traditional approach. Now, you can let the PCB seller worry about other things as you concentrate on perfecting your design.

The fabrication of modern PCB is a great connection between streamlined manufacturing and online technology. This makes it possible to get prototypes in days, the direct shipment of fully assembled products to clients, and quote in just about some minutes. It is profitable to everybody as more innovative products and products of higher quality get to the market faster with fewer creation barriers.

Here, we will be gaining knowledge about Turnkey PCB Assembly. This is known as one of the major developments when talking about PCB assembly.

First, I will throw more light on what turnkey PCB assembly is. Next, we will explain the significance of turnkey PCB assembly to the PCB industry. We will then consider the different techniques utilized in the process, as well as the advantages of utilizing turnkey PCB assembly.

Turnkey Assembly: What Does this Mean?

Due to the inconvenience associated with approaches of traditional PCB assembly. It has become important to work towards an integrated assembly process.

The process is usually very expensive and slow because it involves many players. This is why and how Turnkey PCB assembly came to be.

Turnkey, generally, deals with the providing a full product or service, in a completed and ready to be used. Just order, and the producer makes the quotes, and the remaining is left for him to handle. You finally get a ready-to-use product, when you just need to turn or move the key and all is set!

Therefore, turnkey PCB assembly has to do with consolidating the whole process of PCB assembly. Some turnkey pcb manufacturing companies have even gone the extra mile of including body works to the services of the turnkey PCB assembly.

Turnkey PCB Assembly: Benefits

Work has been made easier with turnkey PCB assembly. This approach’s convenience over traditional options is reflected in the pros below.

Reduced Costs

Adopting the turnkey PCB assembly approach has ensured that the total production cost much cheaper. Usually, it has a packed-up service, which means that some expenses are removed. One area where you can feel this relief most is its freight costs.

It is also easy to procure its components. The assemblers are usually capable of securing great deals with those producers and distributors of the component. This is because they’ve formed a long-term partnership between them.

Great component quality

Procuring these parts is given to the expert assemblers to handle. Their long-term partnership, as well as partnership with the suppliers assists them in acquiring the best quality for these components.

If you are procuring these components yourself, there is a high chance that you’ll be presented with raw deal. This is due to the fact that you may lack the professional experience of buying these components yourself. You may therefore lack the ability to check the quality properly. This becomes worse, if it is your first time.

Quick Lead Time

Consider all the separate phases involved in the assembly of PCB. First of all, you have to contact an establishment to help you with the fabrication of the PCB. You’ll then go on to buy the components, and then eventually contract for the assembly.

It takes an even longer process if the location of these companies is in different nations. For complete turnkey PCB assembly, they are handled altogether. The process involved in procurement is then reduced to just one. Also, communication with partners is eliminated as well. Reducing the quotations and communication reduces any possibility of distortion coming to the project.

Monitoring Ease

Asides from the reduced lead time, a complete turnkey PCB assembly makes sure smooth and easy monitoring happens.

Working with this step, requires that you have experts that will help in monitoring the different stages. There are engineers with great qualifications that will ensure that all the stages are properly perfected. What you have to do is ensure that all stages are perfected, and that the end product is done to meet the best and desired quality.

Simply logging in on the website of the vendor ensures that you work with the whole process. The consequences of having just a vendor could be more comforting, even if this vendor decides to assemble the end product.

Easier Prototyping

When handling PCB assembly traditionally, there’s a need to do the prototypes for all the stages. With total turnkey PCB assembly, you are given some freedom by lessening the time spent and cost of prototyping. All of it is taken care of by the vendor, based on the specifications of the product. This further assists in reducing the time for production.

When the seasoned experts of the vendor handle the prototyping, this means you will likely receive a much better product compared to doing it from your end.

Detecting Problems Early

One experience no one wants to have is realizing you have just made an error after spending so much money on the printed circuit board.

It is better to detect an error which usually happens when prototyping for PCBs before the production of the boards. Ordering these parts separately will expose you to such danger. If you choose full turnkey assembly, the vendor will have to take full responsibility and make things right. This is because the liability as a whole will be on them whenever something goes wrong. Your vendor must have been involved in this for long, and they have and have mechanisms to ensure that early detection happens.

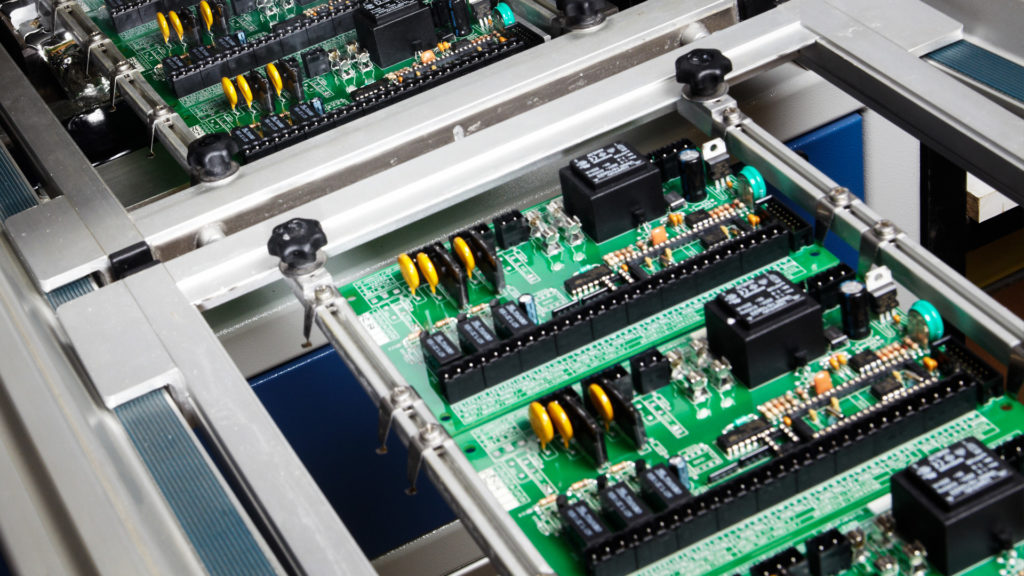

Techniques in the Process of Turnkey PCB Assembly

You can perform turnkey assembly making use of different techniques. This is dependent on your preference, which is usually determined by those attributes of the product you prefer.

Now, let us consider these techniques used in turnkey pcb electronics.

Through Hole Assembly

Here, you mount components of a through hole on a bare PCB. These components of through hole have leads that pass through the holes drilled.

Once these leads are inserted through these holes, the leads are soldered by the assembler on the board’s opposite side. This soldering could be manually done or with automated machines for insertion.

The through hole PCB assembly techniques can be categorized into two major types:

- Radial Lead Components: These have leads, which come out from the body of the component on one side

- Axial Lead Components: These have leads, which passes through one end of the components to the other.

Below are the steps involved in the through hole assembly process

Step 1: Get your surfaces ready for soldering. By so doing, you are doing this to ensure the surface catches the solder properly

Step 2: Place these components on your board. You insert these component leads through the holes set for soldering

Step 3: After inserting the leads, heat the pads and the leads to help melt the solder.

Step 4: Apply the solder to these joints.

Step 5: With iron, touch the solder’s meeting point and its joint until enough solder has been able to flow. Then the board is allowed to cool

Step 6: You inspect the finally assembled board to know if everything was done perfectly, before packaging and dispatching them.

Benefits of the through hole method

- Tolerates high heat

- Physical connections are stronger

- The power handling capacity is better

- Easy prototyping

Weakness of he through hole method

- Longer time for production

- Operation speed is slower

- The production of the board is expensive

Surface Mount Assembly

This technique has to do with the mounting of components to a PCBs surface. This method became well-known from the 1980s. Presently, it has gained more popularity than THT as a frequently used technique for PCB assembly.

In contrast to the through hole technique, these components will not be fitted through the holes. The leads of the components of the surface mount can be found underneath packages that touches the board’s surface. Usually, the process of surface mount is sophisticated, and can’t be done through manual means.

Benefits of Surface Mount Assembly

- Usually, the process is automated and it is faster and simpler

- Great for making lighter, smaller, and powerful designs

- SMT is well known compared to the through hole assembly because its lead count is higher

- The SMT components feature lower inductance and resistance

- Higher capacity for production compared to the through hole technique

Weakness of Surface Mount Assembly

- Surface mount assembly requires higher skill level and higher capital investment compared to through hole assembly

- High possibility of defects due to its small components that are packed inside the board

- Not great for components using high voltage

- Its components are usually very small, and due to this reason, at times, they don’t have enough surface area to mark the ID codes and names of the components.

Mixed PCB Assembly

This involves both the surface mount and through hole assembly. When dealing with applications requiring both capabilities of the THT and SMT combines, then this technology is highly recommended.

With this method, you can have both SMT and THT components put together in one public circuit board. This technique is useful in many applications. Here are some of the areas:

- Sensor boards

- CPUs

- IoT Hardware

- LED lighting products

- Smartphone Accessories

- Sensor boards

- Video processing

- Communication hardware

Benefits of Mixed PCB Assembly

Much larger components having handling capabilities of high power, and smaller with very effective SMT components, will be assembled into one board

Asides from this, components will be mounted on both PCB sides. With this, you’ll have more space to house other components. What this means is that the devices that result will perform better in processing speeds and power handling.

Generally, public circuit boards assembled by mixed techniques means boards combine the strength of both THT and SMT.

Conclusion

We have been able to have a close look at the Turnkey PCB assembly concept. We hope this guide was very useful to you. We also believe that you have been able to widen your knowledge in this regard. You should be able to make better decisions concerning PCB assembly methods.

GET IN TOUCH

Send Us a Message and Learn More About Our Services

Leave a request and we will contact you as soon as possible